A wierd choice for a model this dimension.

I nonetheless bear in mind the sounds (and smells) of the previous paper mill in my hometown. I grew up listening to that the city solely exists due to that paper mill and what number of dad and mom of the children I went to highschool with labored there or maintained its operation. However like many American manufacturing crops earlier than it, it fell silent in 2021 after 157 years of operation, leaving an eerie quietness that echoed fears of impending financial devastation on the neighborhood.

It shares the same story of the Mohnton Knitting Mills manufacturing unit, a number of hours east of the place I grew up, that additionally closed late final 12 months.

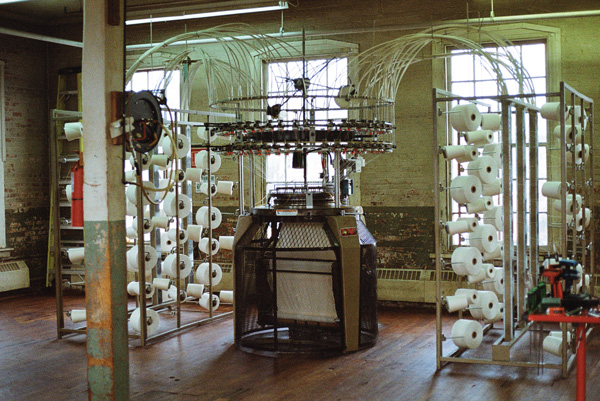

Constructed in 1873, Mohnton Knitting Mills had been a stalwart of the Japanese Pennsylvania textile manufacturing scene since 1906. Based by Aaron Hornberger in Mohnton, PA, the mill has had its justifiable share of highs and lows. From manufacturing hats, T-shirts, World Battle II uniforms, designer clothes traces, and thermal underwear, to getting a stylish following in Japan within the early 2000s for its customized knitwear, the mill had a storied run.

It appeared like issues have been wanting up when Gary Pleam, Hornberger’s great-grandson and firm president, oversaw the sale to Sew Repair in 2017 – however the private stylist model encountered its personal set of issues they usually closed the manufacturing unit’s doorways in 2022, resulting in the lack of 56 jobs.

Buck Mason is an LA-based clothes model with a rugged, minimalist type aesthetic that does not scream for consideration however nails it within the particulars. I’ve change into a fan of their self-described “Southern California type” during the last 10 years as a result of it’s form of like J.Crew however with much less prep influences. I’ve shared outfits with their henleys, jackets, and chinos over time, and they’re included in our Finest Clothes Manufacturers for Males checklist.

Since its Venice Seashore founding in 2013, Buck Mason has saved a portion of their manufacturing home, however they’ve simply introduced how they’ve taken it a step additional: They’ve bought the Mohnton Knitting Mill and close by stitching manufacturing unit, bringing again authentic workers. Now, a number of of their t-shirt traces are manufactured there, with plans to increase to extra objects.

Given the backdrop of the present American clothes manufacturing trade, the choice by Buck Mason to amass the previous Mohnton Knitting Mills and stitching manufacturing unit is not simply one other company enterprise— it is a aware option to diverge from the trail that almost all American firms take as they develop.

Have a look at the numbers. In line with Stephanie Vatz in 2013, the common American family in 1960 spent over 10% of its revenue on clothes and sneakers, equal to roughly $4,000 on the time she reported it. Again then, individuals purchased fewer than 25 clothes per 12 months, with a major 95% of that attire being produced in America.

Quick ahead to as we speak, the place the common American family now spends lower than 3.5% of its finances, underneath $1,800 per 12 months, on clothes and sneakers even supposing we’re buying extra clothes than ever earlier than—nearly 68 items per individual annually. A staggering shift, contemplating solely about 3% of those garments are made in the USA.

The numbers reveal the numerous transformation the American clothes trade underwent over the a long time. In 2019 alone, the U.S. imported a staggering $127.7 billion price of textiles and attire.

This shift had its roots within the mid-Seventies, when massive textile mills and factories started rising in China and different growing nations, providing cheaper labor and the flexibility to effectively handle large-scale orders.

By 1980, main retail chains like Hole Inc. and JCPenney had begun outsourcing manufacturing to those abroad factories. American producers, burdened by greater wages and operation prices, could not compete. By 2002, the enduring denims model Levi’s, synonymous with America, manufactured just about all of their denims abroad. At this level Mohnton Knitting Mills was one of many solely surviving American factories nonetheless making customized knitwear.

My goal right here is not particularly about ‘revitalizing’ American manufacturing. It is an acknowledgement of the complexity of the scenario—financial, cultural, historic.

However let’s not ignore the elephant within the room; this type of enterprise funding requires a parallel dedication from customers who’re keen to pay what’s perceived as a premium value.

A Grown & Sewn t-shirt from Buck Mason, the place each the cotton and shirt are made within the US, begins at $45. It may be a tricky quantity to swallow once we’ve change into accustomed to t-shirts costing $8 to $15.

And the unlucky actuality is that it could be an extremely tough, if not unimaginable, feat for the common individual to attempt to put on solely American-made clothes as we speak. Consider everybody’s completely different wants for sizing and match, aesthetic preferences, the lack to simply discover American-made objects, the apparent important price ticket they’ve inherently and as we speak’s typical client shouldn’t really feel shamed for purchasing what works for his or her wants and their finances.

Given all these components, Buck Mason’s latest funding might sound quixotic. However co-founders Erik Allen Ford and Sasha Koehn aren’t promising to carry again the golden age of American manufacturing, nonetheless, what they’re doing is reminding us of the worth and the price of the issues we put on. And whereas it’ll stay unlikely that many people will be capable of, say, purchase garments for the workplace that have been made within the US as a result of value and availability, we can make investments extra for our enduring staples like a t-shirt with superior cloth and design particulars that can be made in a small American manufacturing unit.

Buck Mason’s funding within the Mohnton Knitting Mills is not going to reverse the tide. It will not reopen all of the shuttered factories or restore all of the misplaced jobs or edit the common client’s expectation for value. But it surely does characterize the uncommon firm of its dimension already making premium merchandise bought at a premium value reinvesting that into American manufacturing.

It could not appear to be a lot—a single firm, one knitting mill, one T-shirt at a time. The closing of the previous paper mill in my hometown wasn’t only a chapter ending in our native trade. Till its closure, it remained the biggest employer with numerous ancillary companies grown up round it to help its operation and its staff. So, when it fell silent final 12 months after 157 years of operation, we did not simply lose jobs. We misplaced a major piece of our id, and have been thrust into an unsure future. And now the one proposal is to show it right into a highschool soccer discipline – which can do little in changing the financial ecosystem that the neighborhood misplaced.

Buck Mason’s buy of Mohnton is not a nostalgic journey or a campaign towards world manufacturing. It is an instance of how an organization can increase whereas investing in a neighborhood, injecting life into an area economic system.

The takeaway is not to champion an ‘America-only’ stance, however to think about the influence of our selections, particularly when it comes to native economies and communities. Buck Mason’s transfer is a reminder that every buy we make, as customers and companies, can go away an enduring mark on the lives of actual individuals, in actual communities, very like the one I grew up in.